Is Cement Board More Expensive Than Plywood

When it comes to choosing materials for your next project, the cement board vs. plywood debate is a big one. I’ve faced this decision more times than I can count. Price is a huge factor, but it’s not just about the initial cost. Let’s break down the real costs of cement board compared to plywood. We’ll look at the price tags and durability, longevity, and where each material fits best in your home projects. If you’re weighing your options and your budget, this is where you’ll find some clear, practical answers. Let’s dive into the nitty-gritty and figure out which material gives you more bang for your buck.

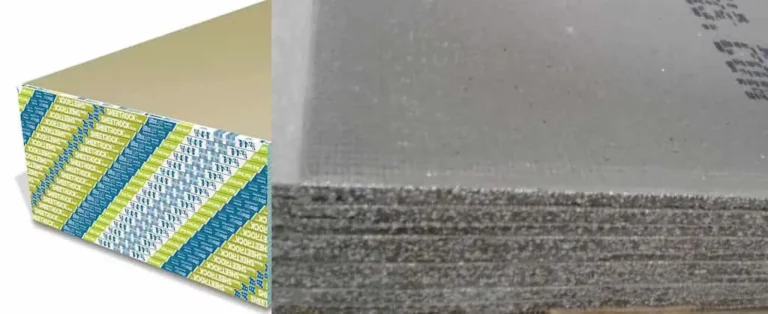

Material Composition Differences

Grasping the distinct properties of material composition is vital when evaluating the robustness of cement board against the sensitivity of plywood to elements from the surroundings.

Cement boards are crafted from a blend of cement, with additives such as cellulose and mica, complemented by modest proportions of PVA and aluminum stearate. This concoction endows cement boards with their impressive imperviousness to moisture, decay, and combustion. They furnish a solid, inflexible surface, perfectly suited for anchoring grout and tiles firmly.

On the other hand, plywood is composed of numerous strata of wood veneer sourced from either hardwood or softwood species, bonded by adhesives. These strata may succumb to environmental shifts; plywood is susceptible to damage from moisture and can distort or contort in response to variations in humidity or temperature levels. This renders plywood a suboptimal base for locales routinely exposed to damp conditions.

Hence, the variances in material composition are pivotal in judging the appropriateness of each substance for particular tasks. While plywood might initially seem a cost-saving choice, cement boards are superior in durability and efficacy, particularly in rigorous settings where moisture presence and structural stability are vital factors. Consider these inherent qualities when selecting construction materials.

Comparing Moisture Resistance

When comparing the attributes of cement board to plywood, one outstanding benefit of the former is its robust defense against moisture. In choosing materials for a building or remodeling endeavor, assessing how each reacts to water is pivotal.

Cement board excels in damp conditions. Unlike plywood, it resists swelling, degradation, or structural compromise when saturated. This attribute renders it a preferred option for zones frequently in contact with water. Below is a brief exposition of the superiority of cement board in environments prone to moisture:

- Water-Resistant Nature: Cement board retains its dimensions and durability, even with extended water contact.

- Ideal for Humid Spaces: It’s the optimal choice for bathrooms, kitchens, and cellars, where persistent moisture is common.

- Barrier to Moisture-Induced Harm: A cement board’s stalwart resistance to moisture significantly reduces the hazard of fungal growth and damage to the structure, in contrast to plywood’s vulnerabilities.

Bearing in mind that moisture-related repairs can be expensive, opting for materials resilient to humidity and direct contact with water, such as cement board, can spare you distress and financial burdens down the line. In the contest of plywood versus cement in resisting moisture, cement board stands out as the definitive victor.

Stability and Durability Factors

Evaluating the longevity of construction materials, cement board outshines plywood in steadfastness and enduring qualities. This is due to its robust composition and resistance to deterioration. Conversely, plywood is prone to bending and can distort under fluctuating humidity or temperature, making it less suitable for moist settings.

The steadfastness and enduring nature of cement board become particularly advantageous in areas prone to wetness. Its impressive resistance to moisture drastically lowers the likelihood of harm to grout or tiles, which are frequent complications in humid environments. This resilience guarantees that cement board offers superior enduring performance and upholds its structural integrity, even amidst water or intense moisture.

Additionally, cement board possesses a superior capacity to bear substantial loads compared to plywood. This trait is pivotal for the installation of hefty materials such as porcelain tiles or for vertical uses, including countertops or surrounds for fireplaces. Its unyielding nature against movement and steadfast form ensures the board’s continued status as a robust and reliable selection for building purposes. Despite its greater initial expense relative to plywood, cement board represents a wise allocation of funds.

Installation Process Overview

Embark on your tile installation endeavor by affixing the cement board straight onto the subfloor or wall studs. This method proves less intricate than the preparation of plywood, which generally calls for extra steps to ensure waterproofing. The cement board furnishes a steadfast surface imperative for tile application success. Contrary to plywood, it spares you from extensive groundwork to achieve a tiling-ready plane.

Here’s a succinct guide to laying cement board:

- Dimensioning and Sectioning: Gauge the intended area for the cement board placement. Utilize a utility blade or a carbide-tipped instrument to tailor the cement board to the designated dimensions.

- Stabilization of the Panel: Arrange the cement board over the subfloor or align it with wall studs, fastening it in place with screws tailored for cement board attachment, thus guaranteeing a secure and even base for the tiles.

- Joint Strengthening: Strengthen the joints by affixing fiberglass mesh tape to the cement board panel seams, bolstering stability and mitigating the risk of seam fractures post-tile installation.

This tactical procedure affords a robust underpinning for your tiles, steering clear of the frequent complications tied to installing tiles over substrates that lack stability, such as plywood.

Analyzing Cost Variables

When scrutinizing the various expenses associated with construction materials, it’s evident that the initial outlay for cement board surpasses that of plywood. Yet, appraising long-term financial implications tied to upkeep and endurance is prudent. Cement board offers a shield against moisture, rot, and combustion, which may culminate in fiscal benefits as time progresses, especially in moisture-rich or fire-sensitive locales.

Conversely, plywood presents an economical option upfront but may necessitate ancillary actions such as applying water-resistant treatments for usage in damp conditions, incrementing the aggregate cost. Vulnerability to deformation and degradation upon prolonged moisture exposure indicates a higher probability of needing replacement or repair, a significant aspect to evaluate for those selecting materials for construction endeavors.

Moreover, the superior load-bearing threshold of cement board enhances its structural integrity, positioning it as a stalwart selection where robustness is imperative. On the other hand, should the project prioritize malleability and a lighter touch, plywood’s featherweight characteristic could counterbalance its prospective enduring expenses.

Selecting the appropriate material hinges on the distinctive requirements of your project and your predilection for investing in durability against immediate expenditure savings.

Frequently Asked Questions

Which Is Better Cement Board or Plywood?

Cement board outshines plywood in areas prone to dampness and where tiling is intended, owing to its superior moisture resistance and firmness. On the other hand, plywood offers pliability but falls short in environments that are moist or bear substantial weight.

What Is Cement Board Most Often Used For?

Cement board is often selected as an underlayment for tile in moisture-prone areas. Its resilience against dampness ensures a robust and unwavering foundation, enhancing the longevity of tile work.

What Are the Advantages of Cement Board?

Cement board is renowned for its exceptional endurance, imperviousness to moisture. It provides a steadfast platform for tile application, presenting a favorable balance of cost when juxtaposed with plywood, especially in zones susceptible to water.

Can Cement Board Bear Weight?

Cement board indeed demonstrates a robust capacity for supporting substantial loads, proving to be an exemplary choice for installations of dense tiles and in regions requiring a durable and enduring surface. It surpasses plywood in terms of its ability to bear loads.

Conclusion

When deciding between construction materials, you’re weighing plywood’s immediate cost-effectiveness against the cement board’s enduring attributes.

The latter’s impressive defiance against moisture, rot, and combustion makes it a wise choice for moisture-prone areas such as bathrooms. Though your budget might initially bristle at the expense, the long-term savings afforded by its longevity and stability could prove to be financially prudent.